-

Initial excavation of the turbine foundation

-

52” wide excavating bucket – 3 yard capacity

-

Foundation excavation

65 – 70 ft diameter hex, 9 - 10 ft deep

-

3 - 4” concrete floor base (rat slab) for rebar

-

Setting up the rebar structure

-

Bolt pattern ring

15 ft. bolt pattern ring form to be centered on the foundation base

-

Bolt ring guide

-

Rebar foundation curved to center ring

-

Concrete delivery

Pumper truck pumps 23 loads ( 240 yards ) of concrete into rebar form

-

Concrete delivery

Each concrete truck driver inserts his load ticket in the mail box on top of the pumper to indicate the completion of their load

-

Base platform is filled with concrete

-

Center support

Top center base form over platform base

-

Center support

Note the size of the nut compared to the brick

-

Final foundation completed

-

Final preparation of center support

Dirt filler packed over foundation base up against center support

-

Electrcal conduit

Burying electrical conduit from foundation to future electrical box (transformer)

-

Electrical trench

Electrical trench extends from tower to tower to the sub-station

-

Wiring

Top – insulated electrical wire. Bottom - copper ground wire

-

Computer control center and electrical transformer

White shrink wrap covers computer control center that is placed over the tower base, green electrical transformer is set beside tower base

-

Inside the electrical transformer

-

Nose cone shipped in shrink wrap for protection

-

Inside the nose cone

Three total motors for changing the pitch of the blades

-

Nacelle arrives on 9 axle trailer

-

Nacelle

Located on top of the tower and houses the main components such as the gear box, generator, main bearing and shaft

-

Nacelle

Size - 29 ft x 11.5 ft x 12.5 ft. Weight - 114,640 lbs (57.32 tons)

-

Top of nacelle

-

Inside nacelle – generator and gear box

-

Variable speed, doubly-fed induction generator

Maximum power output - 1.5 MW or 1,500 kW. Dimensions – 11 ft x 5.5 ft x 6 ft. Weight – 17,636 lbs

-

Main power shaft – approximately 23” diameter

-

Three tower sections

Base diameter = 14.92 feet

-

Three tower sections

Bottom section – 73 ft long, weighs 64 tons. Mid section - 82 ft long, weighs 42 tons. Top section - 98 ft long, weighs 33 tons

-

Cleaning tower components

All tower components are thoroughly washed inside and out before assembly

-

Ladder inside the tower base

-

Red (mid-size) crane positions bottom two tower sections

-

Final tower section is lifted into position

-

Final tower section fastened into position

-

Nacelle lifted to position on top of tower

-

Nacelle fastened to top of tower

-

Arrival of the blades

122 ft. long blades arrive on site. Each blade weighs approximately 13,000 pounds

-

Blades are bolted to the hub

Rotor is composed of three blades and a hub. Diameter - 252 feet. Overall weight - 73,193 pounds (36.6 tons)

-

Blades are bolted to the hub

After blades are bolted to hub, marks are made to easily identify any movement

-

Lifting the rotor assembly and blades

Rotor being wrapped into crane cradle hook (note man in orange safety vest)

-

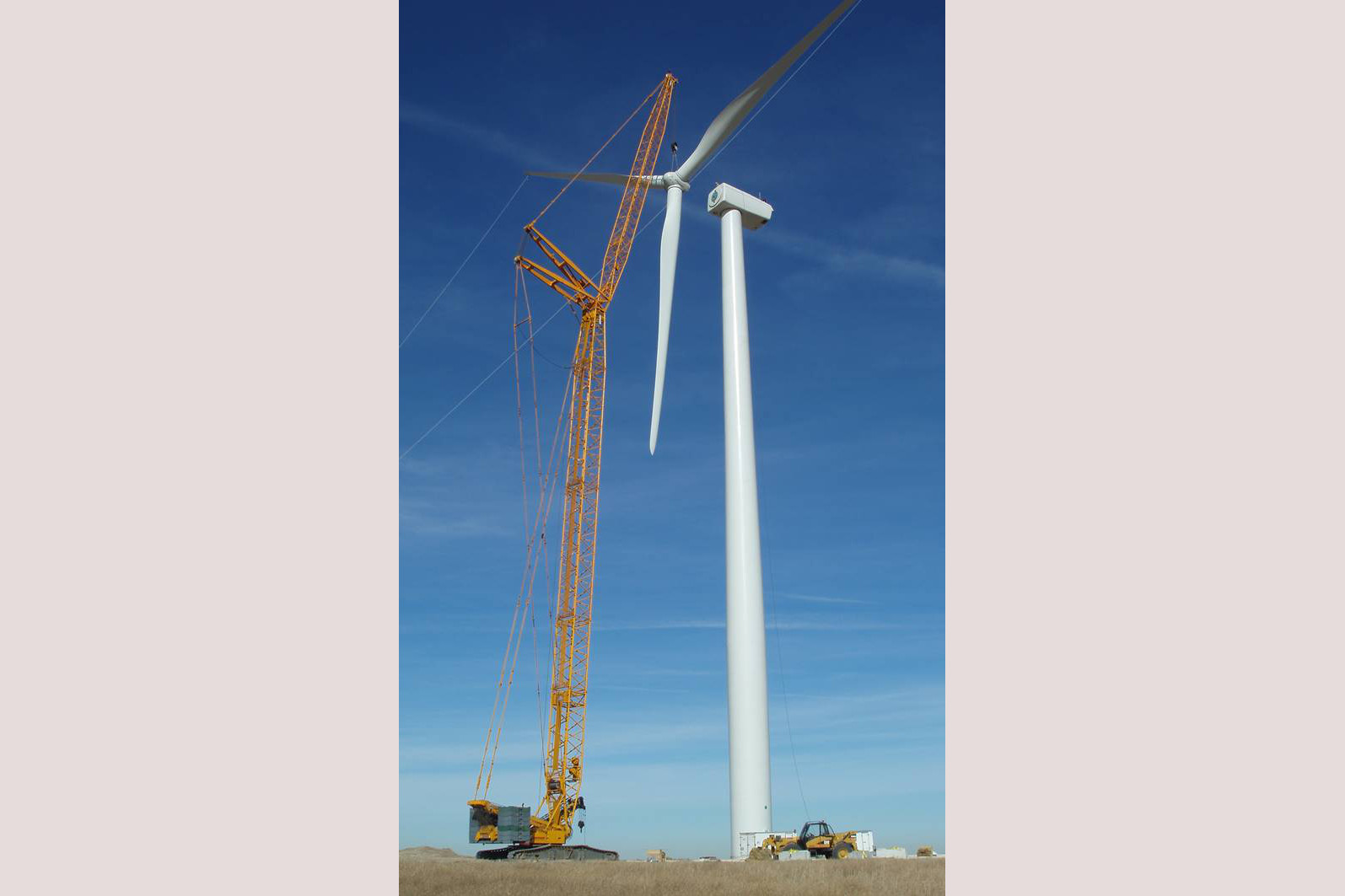

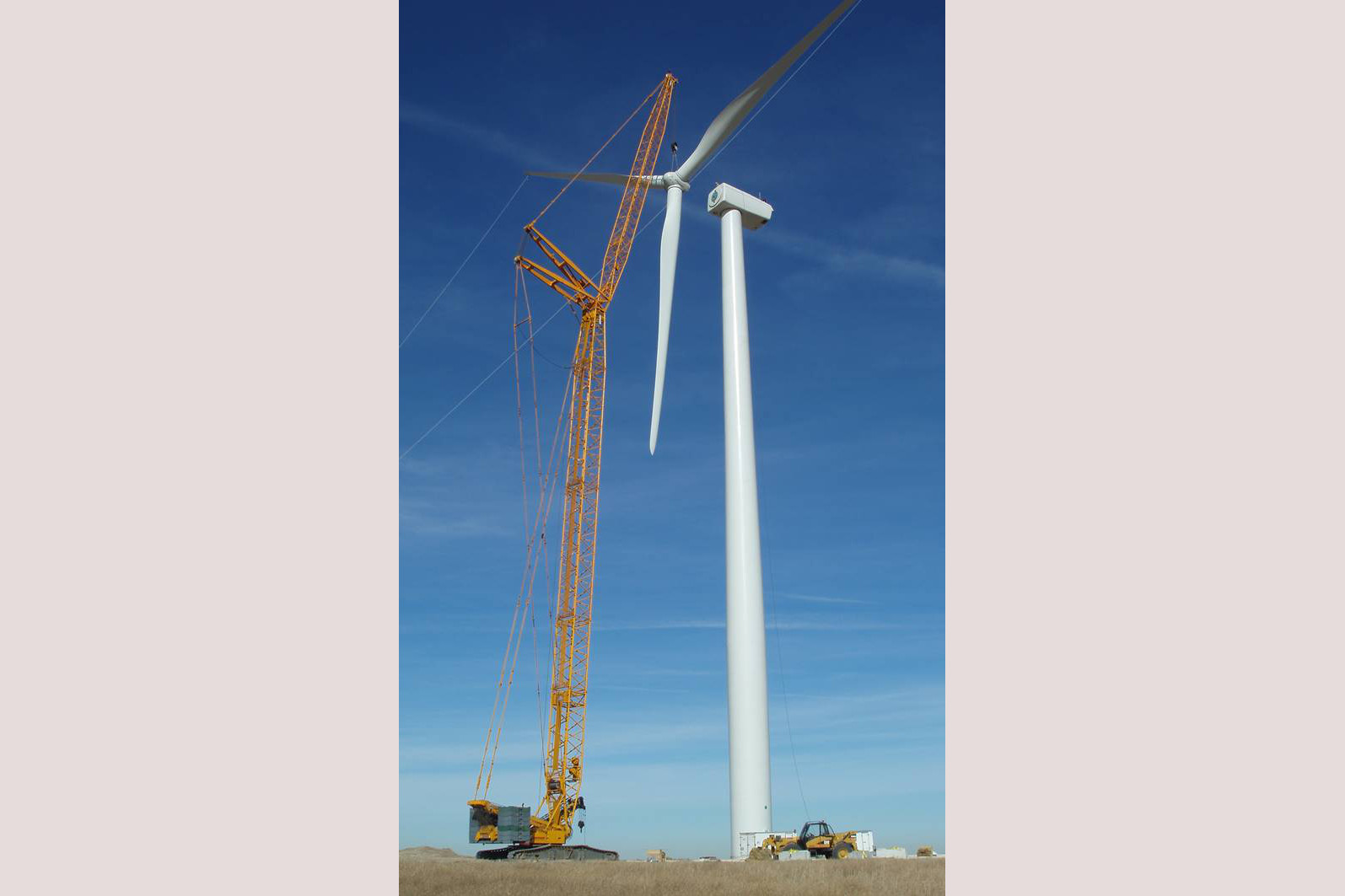

Lifting the rotor assembly and blades

Large crane to lift rotor assembly & small crane supports bottom blade from dragging

-

The blades go up!

-

The blades go up!

-

Finishing touches

Technician crawls up tower, through the nacelle, and into the hub to bolt rotor to nacelle

-

Ready for service!

Tower height - 263 feet. Total height of tower & blade in vertical position - 389 feet. Complete weight of tower, nacelle and rotor - 232 tons

-

View 21st Century technology… providing electricity for our future!

Initial excavation of the turbine foundation

Initial excavation of the turbine foundation 52” wide excavating bucket – 3 yard capacity

52” wide excavating bucket – 3 yard capacity Foundation excavation65 – 70 ft diameter hex, 9 - 10 ft deep

Foundation excavation65 – 70 ft diameter hex, 9 - 10 ft deep 3 - 4” concrete floor base (rat slab) for rebar

3 - 4” concrete floor base (rat slab) for rebar Setting up the rebar structure

Setting up the rebar structure Bolt pattern ring15 ft. bolt pattern ring form to be centered on the foundation base

Bolt pattern ring15 ft. bolt pattern ring form to be centered on the foundation base Bolt ring guide

Bolt ring guide Rebar foundation curved to center ring

Rebar foundation curved to center ring Concrete deliveryPumper truck pumps 23 loads ( 240 yards ) of concrete into rebar form

Concrete deliveryPumper truck pumps 23 loads ( 240 yards ) of concrete into rebar form Concrete deliveryEach concrete truck driver inserts his load ticket in the mail box on top of the pumper to indicate the completion of their load

Concrete deliveryEach concrete truck driver inserts his load ticket in the mail box on top of the pumper to indicate the completion of their load Base platform is filled with concrete

Base platform is filled with concrete Center supportTop center base form over platform base

Center supportTop center base form over platform base Center supportNote the size of the nut compared to the brick

Center supportNote the size of the nut compared to the brick Final foundation completed

Final foundation completed Final preparation of center supportDirt filler packed over foundation base up against center support

Final preparation of center supportDirt filler packed over foundation base up against center support Electrcal conduitBurying electrical conduit from foundation to future electrical box (transformer)

Electrcal conduitBurying electrical conduit from foundation to future electrical box (transformer) Electrical trenchElectrical trench extends from tower to tower to the sub-station

Electrical trenchElectrical trench extends from tower to tower to the sub-station WiringTop – insulated electrical wire. Bottom - copper ground wire

WiringTop – insulated electrical wire. Bottom - copper ground wire Computer control center and electrical transformerWhite shrink wrap covers computer control center that is placed over the tower base, green electrical transformer is set beside tower base

Computer control center and electrical transformerWhite shrink wrap covers computer control center that is placed over the tower base, green electrical transformer is set beside tower base Inside the electrical transformer

Inside the electrical transformer Nose cone shipped in shrink wrap for protection

Nose cone shipped in shrink wrap for protection Inside the nose coneThree total motors for changing the pitch of the blades

Inside the nose coneThree total motors for changing the pitch of the blades Nacelle arrives on 9 axle trailer

Nacelle arrives on 9 axle trailer NacelleLocated on top of the tower and houses the main components such as the gear box, generator, main bearing and shaft

NacelleLocated on top of the tower and houses the main components such as the gear box, generator, main bearing and shaft NacelleSize - 29 ft x 11.5 ft x 12.5 ft. Weight - 114,640 lbs (57.32 tons)

NacelleSize - 29 ft x 11.5 ft x 12.5 ft. Weight - 114,640 lbs (57.32 tons) Top of nacelle

Top of nacelle Inside nacelle – generator and gear box

Inside nacelle – generator and gear box Variable speed, doubly-fed induction generatorMaximum power output - 1.5 MW or 1,500 kW. Dimensions – 11 ft x 5.5 ft x 6 ft. Weight – 17,636 lbs

Variable speed, doubly-fed induction generatorMaximum power output - 1.5 MW or 1,500 kW. Dimensions – 11 ft x 5.5 ft x 6 ft. Weight – 17,636 lbs Main power shaft – approximately 23” diameter

Main power shaft – approximately 23” diameter Three tower sectionsBase diameter = 14.92 feet

Three tower sectionsBase diameter = 14.92 feet Three tower sectionsBottom section – 73 ft long, weighs 64 tons. Mid section - 82 ft long, weighs 42 tons. Top section - 98 ft long, weighs 33 tons

Three tower sectionsBottom section – 73 ft long, weighs 64 tons. Mid section - 82 ft long, weighs 42 tons. Top section - 98 ft long, weighs 33 tons Cleaning tower componentsAll tower components are thoroughly washed inside and out before assembly

Cleaning tower componentsAll tower components are thoroughly washed inside and out before assembly Ladder inside the tower base

Ladder inside the tower base Red (mid-size) crane positions bottom two tower sections

Red (mid-size) crane positions bottom two tower sections Final tower section is lifted into position

Final tower section is lifted into position Final tower section fastened into position

Final tower section fastened into position Nacelle lifted to position on top of tower

Nacelle lifted to position on top of tower Nacelle fastened to top of tower

Nacelle fastened to top of tower Arrival of the blades122 ft. long blades arrive on site. Each blade weighs approximately 13,000 pounds

Arrival of the blades122 ft. long blades arrive on site. Each blade weighs approximately 13,000 pounds Blades are bolted to the hubRotor is composed of three blades and a hub. Diameter - 252 feet. Overall weight - 73,193 pounds (36.6 tons)

Blades are bolted to the hubRotor is composed of three blades and a hub. Diameter - 252 feet. Overall weight - 73,193 pounds (36.6 tons) Blades are bolted to the hubAfter blades are bolted to hub, marks are made to easily identify any movement

Blades are bolted to the hubAfter blades are bolted to hub, marks are made to easily identify any movement Lifting the rotor assembly and bladesRotor being wrapped into crane cradle hook (note man in orange safety vest)

Lifting the rotor assembly and bladesRotor being wrapped into crane cradle hook (note man in orange safety vest) Lifting the rotor assembly and bladesLarge crane to lift rotor assembly & small crane supports bottom blade from dragging

Lifting the rotor assembly and bladesLarge crane to lift rotor assembly & small crane supports bottom blade from dragging The blades go up!

The blades go up! The blades go up!

The blades go up! Finishing touchesTechnician crawls up tower, through the nacelle, and into the hub to bolt rotor to nacelle

Finishing touchesTechnician crawls up tower, through the nacelle, and into the hub to bolt rotor to nacelle Ready for service!Tower height - 263 feet. Total height of tower & blade in vertical position - 389 feet. Complete weight of tower, nacelle and rotor - 232 tons

Ready for service!Tower height - 263 feet. Total height of tower & blade in vertical position - 389 feet. Complete weight of tower, nacelle and rotor - 232 tons View 21st Century technology… providing electricity for our future!

View 21st Century technology… providing electricity for our future!